3D Printing

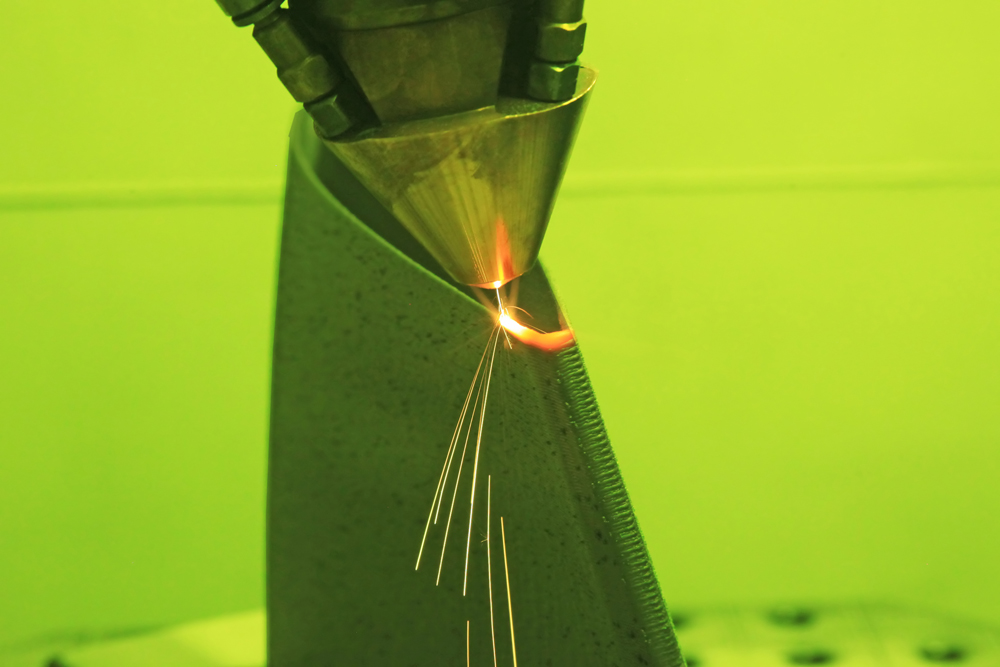

BMI Injection Molding provides 3D printed components using the latest technology and resins from Markforged Manufacturing. 3D technology offers direct manufacturing. We can go right from your idea to a physical part. We’ll take your digital file derived from computer aided design (CAD) software, slice that into 2D layers, and build on those layers to manufacture a component.

Advantages

BMI’s rapid advances in 3D printing and prototyping offer multitudes of possibilities for parts development. 3D printing also offers the advantages of shorter lead times, design freedom, and lower costs. We can produce a small or large number of parts with our 3D process.

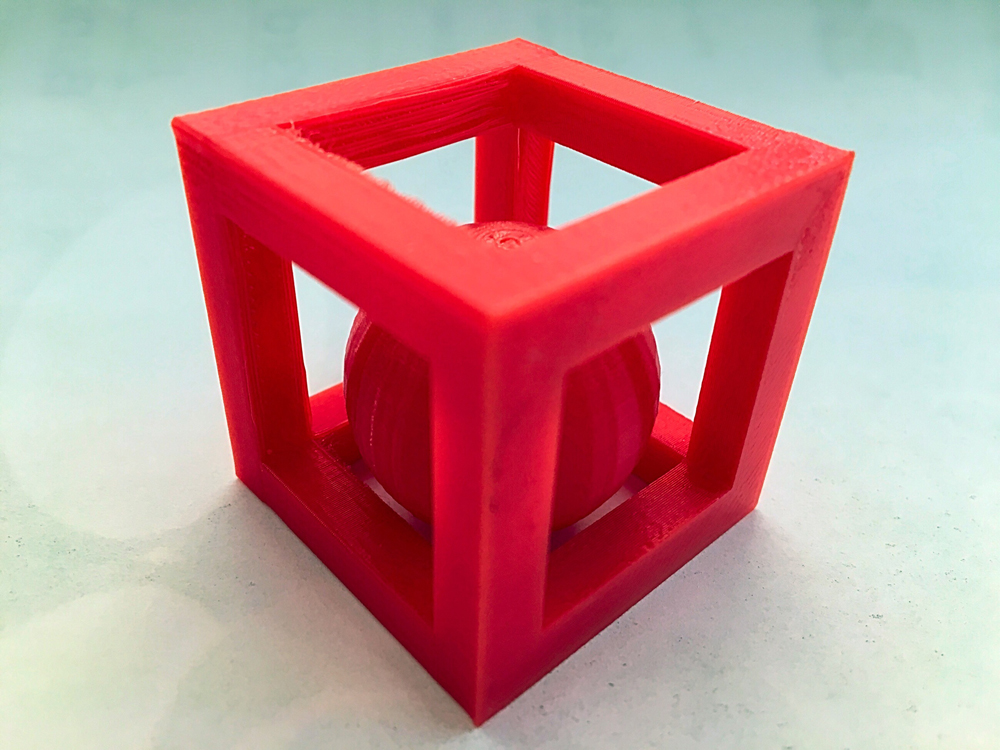

Design Complexity

Because of computer assisted design and the flexibility that 3D printing offers, parts of unusual or complex sizes can be produced. 3D printing allows for flexible orientation. A part may be oriented at an angle, lying flat, or standing vertical. Traditional part production processes don’t allow the complexity of design that 3D printing can offer. As with CNC machining, orientation factors into the outcome of surfaces and details on a 3D printed part. 3D printing builds one 2D layer at a time, so individual lines can appear as ribbed surfaces on parts. Some build orientations are better for square or curved features, and delicate features require special consideration. Applications with higher instances of warp or material deformation must account for large flat surfaces during build orientation. How a part is oriented determines where supports are added or needed within a build. Support can affect the material finish and accuracy of a 3D printed component. Because of BMI’s expertise in 3D printed parts technology, we can account for these factors and have introduced materials that are appropriate for final manufacture, which in turn has introduced the possibility of manufacturing finished components.

Lead Time

Lead time can be a critical factor in production. 3D printing can allow for quick production of a prototype or part. As designs and specifications change, 3D parts can be modified and re-printed in a short amount of time. Our 3D Printing services offer the advantage of the inexpensive production of small numbers of parts. BMI can produce a small or large amount of 3D printed parts to meet your project needs.

Industries

3D Printing is not just for prototyping. 3D printed parts are used in a variety of industries, including but not limited to:

- Low volume production tooling

- Aerospace manufacturing

- Medical devices

- Automotive applications

- Manufacturing large models used by multiple industries

Cost

3D parts can be built from the bottom up and do not require the development or modification of tooling. 3D printed parts reduce manufacturing costs through several key advantages offered by this technology:

- Zero tooling

- Zero cost complexity

- Reduced labor

BMi is an IATF 16949:2016 Quality Supplier. Our engineers can assist you from initial idea to a functional physical part. BMI offers molded component solutions, from product design assistance to finished production Injection Molded components and assemblies. Serving the Automotive, Medical, Industrial, and Consumer markets, our high quality Plastic components consistently exceed customer expectations.