Sonic Welding Services

BMI offers secondary assembly and finishing processes, including sonic welding. Sonic welding can be used for plastic part components and plastic assemblies for applications where it was not possible to mold into a single piece. Parts of similar material can be joined together without the use of hardware or fasteners to give you a clean and strong joint.

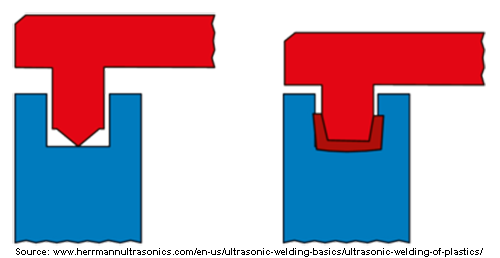

BMI’s Sonic Welding process utilizes high-frequency mechanical motion to a joint to be welded. The motion causes friction between the surfaces, resulting in a build-up of heat that melts the material at the joint. When the material cools, it leaves a solid weld that is strong and durable. Sonic welding is a preferred method for thermoplastic parts. It provides speed and effectiveness.

Welded parts seldom require any touch ups. So sonic welding is a favored choice for automation. A variety of thermoplastic materials can be welded together in multiple applications. Sonic welding can also be used with two different thermoplastic materials if they have similar melting points. Sealed components such as valves, headlights and air handling benefit from the sonic welding process because it doesn’t introduce any additional materials into the sealed area.

Sonic welding is fast, efficient, non-contaminating and requires no consumables. It produces a clean weld site with highly uniform joint quality, providing consistency, reliability and exceptional performance. Sonic welding can be customized to fit exact specifications of welded parts. It’s ideal for assembling parts with delicate internal electronic components and can be used for ultrasonic insertion, ultrasonic staking, stud welding, degating, or spot welding.

BMI provides plastic sonic welding services as a secondary operation to injection molded plastics parts, and as a custom service to customers needing only ultrasonic welding. Our experience and skills in part production and sonic welding machinery allows us to deliver the best solutions in sonic welding. Our sonic welding services can handle any application in the automotive, medical or electronics industries.